1. What are UN Certified Bags?

UN Certified Bags are a type of Flexible Intermediate Bulk Container (FIBC) that meet the United Nations (UN) certification standards outlined in the “Orange Book” (Recommendations on the Transport of Dangerous Goods). These bags are mandatory for the transportation and storage of hazardous materials, such as flammable chemicals, toxic substances, corrosive agents, chemical powders, industrial waste, and low-level radioactive materials.

In contrast, standard Jumbo Bags (non-UN certified) are only suitable for non-hazardous goods like cement, fertilizers, and agricultural products.

2. Rigorous Testing for UN Certification

To achieve UN certification, the bags must undergo a series of stringent tests conducted by accredited laboratories. These tests include:

- Top Lift Test: The bag, fully loaded, is lifted with a load six times its Safe Working Load (SWL) for 5 minutes without failure.

- Drop Test: The fully loaded bag is dropped from a specific height without any leakage:

- Packing Group I: 1.8 meters

- Packing Group II: 1.2 meters

- Packing Group III: 0.8 meters

- Topple Test: The bag is tilted from the same heights as the Drop Test to ensure no spillage occurs.

- Righting Test: The bag’s ability to return to an upright position after being tilted is evaluated.

- Tear Test: The bag is tested for resistance to tearing.

- Stacking Test: The bag is subjected to heavy stacking loads for an extended period to ensure durability.

- Vibration Test: The bag is vibrated for 60 minutes to simulate transportation conditions.

Only bags that pass all these tests are granted UN certification, which is typically valid for a specific production batch.

3. Classification by Packing Group (Hazard Levels)

UN Certified Bags are categorized based on the level of danger of the goods they carry:

- X: High danger (Packing Group I) – Rarely used for FIBCs.

- Y: Medium danger (Packing Groups II & III) – Most commonly used.

- Z: Low danger (Packing Group III).

4. UN Marking on Bags

Every UN Certified Bag must display a clear and durable label with a certification code. For example:

UN 13H3/Y/01 25/VN/ABC/5000/1000

Here’s what the code means:

- UN: United Nations symbol.

- 13H1/H2/H3/H4: Bag type:

- 13H1: Woven PP fabric, uncoated, no liner.

- 13H2: Woven PP fabric, coated, no liner.

- 13H3: Woven PP fabric, uncoated, with liner.

- 13H4: Woven PP fabric, coated, with liner (most common for hazardous goods).

- X/Y/Z: Packing Group classification (as explained above).

- Month/Year: Date of manufacture.

- Country Code: Certification country (e.g., VN for Vietnam, USA for the United States).

- Manufacturer Name/Abbreviation: Name or code of the manufacturer.

- Stacking Load (kg): Maximum weight the bag can withstand when stacked.

- Maximum Load (kg): Safe Working Load (SWL) plus the bag’s weight.

5. Common Specifications

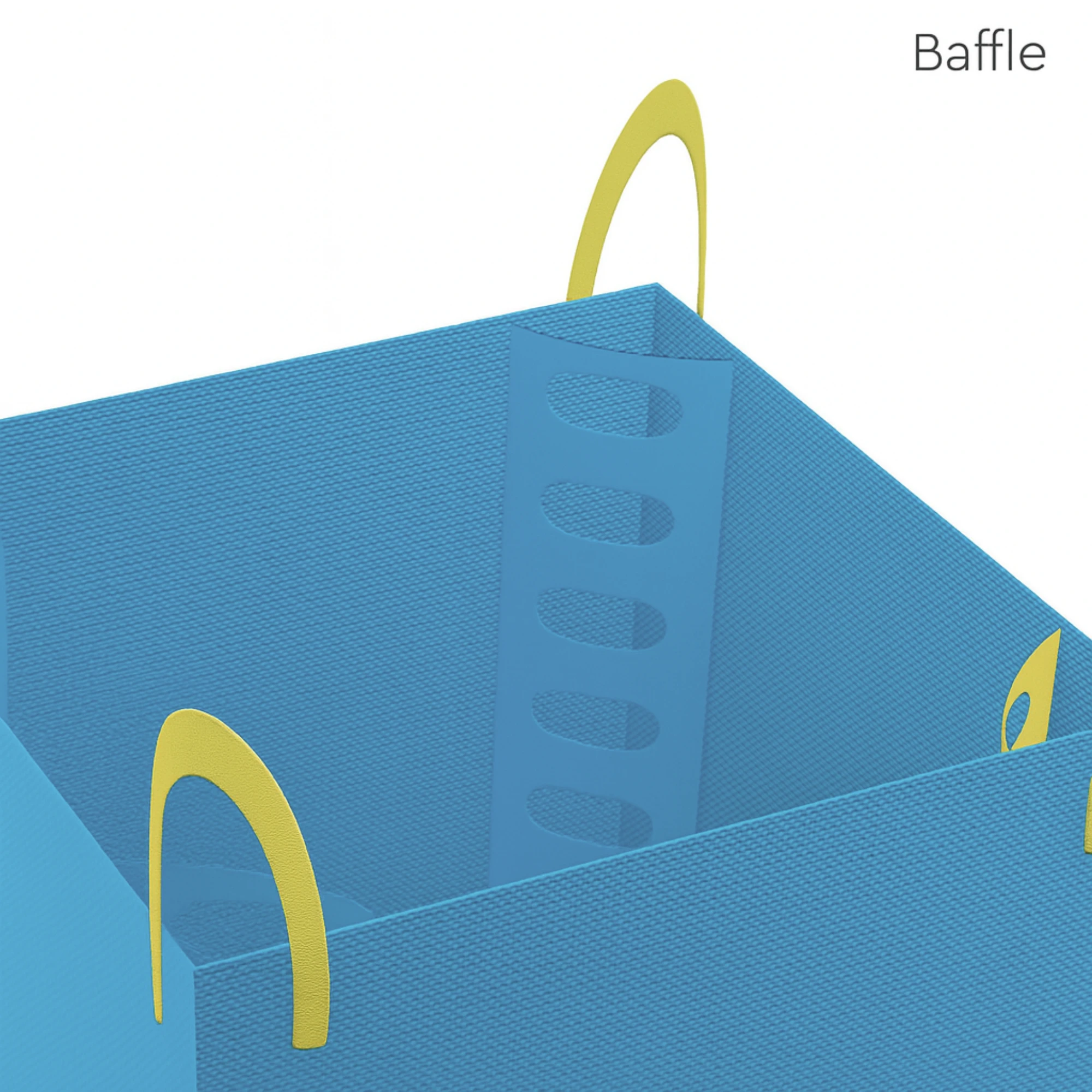

- Material: Virgin woven polypropylene (PP), with anti-static properties (Type B/C/D if required).

- Load Capacity: 500–2000 kg (typically 1000 kg).

- Dimensions: Commonly 90x90x120 cm, but customizable.

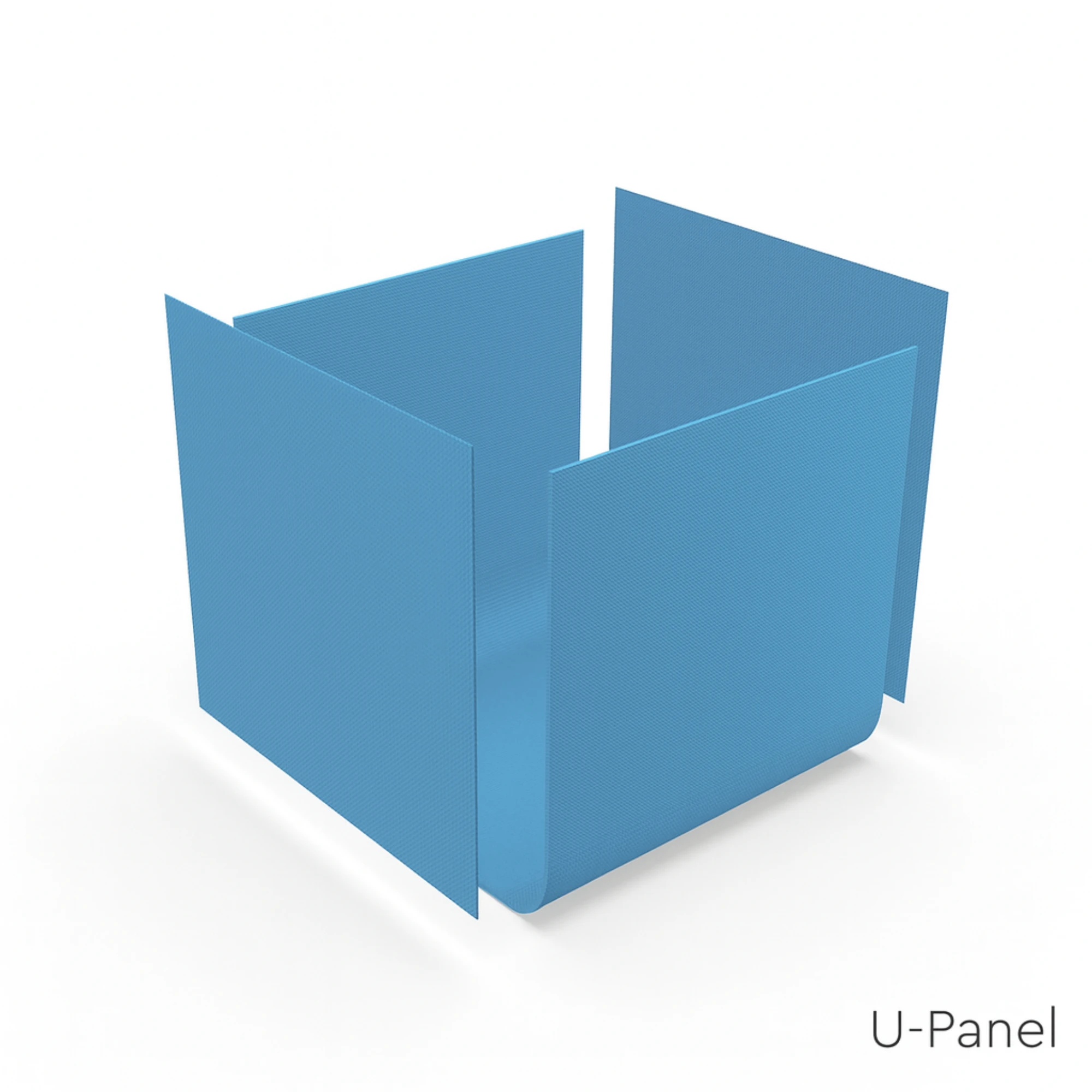

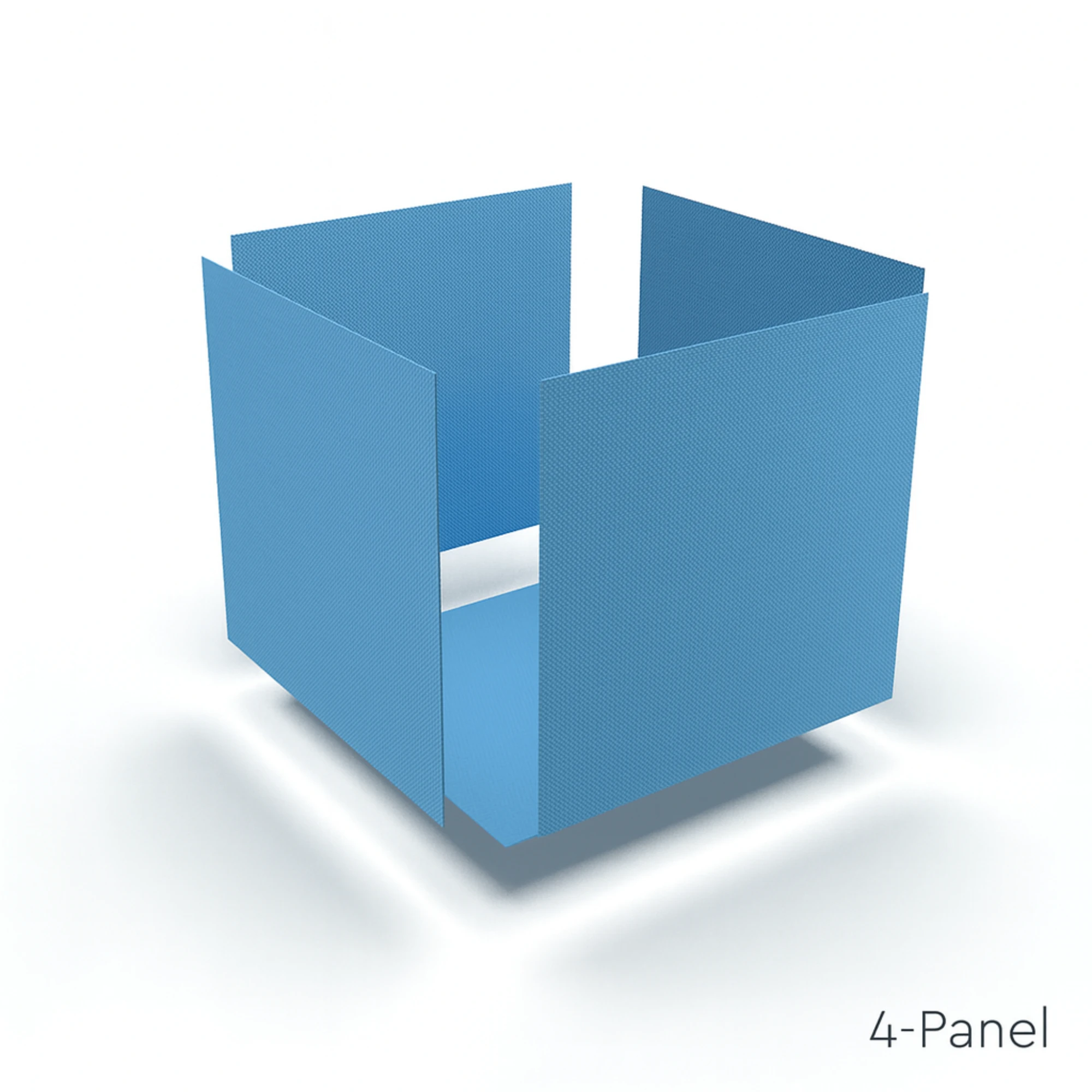

- Design Features: Filling spout, discharge spout, 4 lifting loops, optional PE liner for moisture resistance.

- Safety Factor: Typically 6:1 for hazardous goods.

UN Certified Bags are essential for ensuring the safe handling and transport of dangerous goods, meeting international safety standards and regulations.