U-Panel bulk bags are engineered using a single U-shaped piece of 100% polypropylene that forms the base and two vertical sides. This structural configuration enhances load distribution, improves shape retention, and delivers stable performance when handling heavy, dense, or uneven-flow materials.

Choose U-Panel FIBCs when you need a cost-effective, durable, and versatile bag design for general-purpose industrial applications.

Key Features of U-Panel FIBC Bags

anetora provides U-Panel jumbo bags with consistent quality and customizable technical specifications:

Safe Working Load (SWL): 500 kg to 2,000+ kg

Safety Factor: 5:1 or 6:1

Material: 100% virgin polypropylene, coated or uncoated

Construction: U-shape base + 2 side panels

Liner Options: PE/PA liners from 1 to 7 layers

Size Range: 50 cm to 120 cm+ in length, width, and height

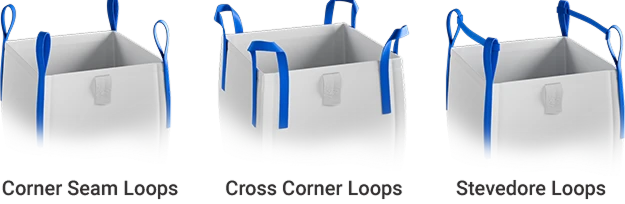

Customization: Filling and discharge spouts, duffle tops, dust-proof seams, anti-skid treatment, 1–4 side printing

Each U-Panel bag is designed for reliable performance across a wide range of products, especially where stability, load control, and easy handling are required.

What Makes a U-Panel FIBC Different?

- Stable Load Distribution

The continuous U-shaped base improves stress distribution and reduces the risk of deformation under heavy loads.

- Improved Shape Retention

Compared to circular bags, U-Panel FIBCs maintain their shape more effectively, enhancing stacking efficiency and warehouse space utilization.

- Cost-Efficient Construction

With only three primary panels, U-Panel designs minimize fabric waste and support highly competitive pricing without compromising strength.

- Smooth Filling & Discharge

Straight side walls and a wide opening help materials flow more efficiently during loading and unloading.

U-Panel FIBCs are widely used in construction, agriculture, chemicals, plastics, food ingredients, minerals, waste management, and pharmaceuticals.