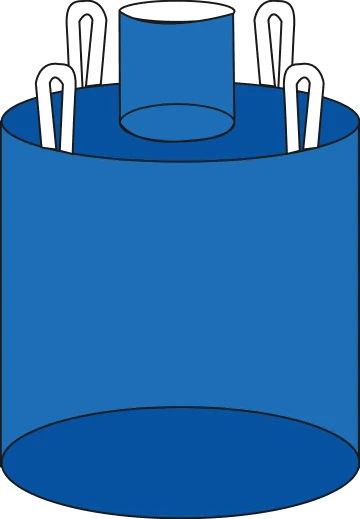

Circular FIBC bags, also known as tubular bags, are among the most common and economical designs in the big bag family. They are constructed using two main components: the body tube and the base.

Key Structural Features

- Seamless Tubular Fabric: The body is woven into a continuous tubular fabric, forming all four side walls without vertical seams.

- Minimal Stitching: Stitching is only required at the top and bottom, reducing the number of seams compared to other bag types.

- Shape When Filled: Although the fabric is tubular, the bag expands into a square or rectangular shape when filled. However, it holds a square shape less effectively than 4-panel or U-panel bags, tending to bulge slightly into a rounded form.

Key Advantages

- Superior Strength and Durability

- The seamless body eliminates vertical seams, which are common weak points in other designs.

- This reduces the risk of tearing or seam failure, making circular bags ideal for heavy loads, fine powders, and flowable materials.

- Space-Saving Storage

- When empty, circular bags fold flat and stack compactly, requiring less storage space compared to more rigid designs.

- Ease of Handling

- The flexible design allows for smoother filling, discharging, and lifting using standard equipment like forklifts or pallet jacks.

- Cost-Effectiveness

- The simpler manufacturing process (fewer seams) lowers production costs.

- Ideal for high-volume orders, offering excellent value per unit.

- Reusable multiple times with proper care.

Common Applications

Circular FIBC bags are widely used across various industries, including:

- Agriculture: Storing grains, seeds, fertilizers, and animal feed.

- Construction: Transporting sand, gravel, aggregates, and other bulk building materials.

- Food Industry: Packing sugar, flour, starch, and other dry food products (using food-grade certified bags).

- Chemicals & Minerals: Containing plastic pellets, powders, and minerals (can be combined with Type B, C, or D antistatic fabrics when required).