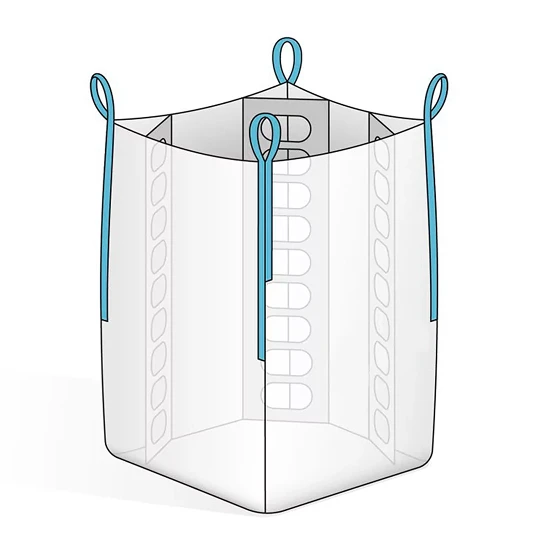

Baffle FIBC bags, also known as Q-bags, formstable bags, or baffled bulk bags, are a specialized type of flexible intermediate bulk container (FIBC) designed to maintain a square or rectangular shape when filled. Unlike standard FIBCs that can bulge or “belly” outward, baffle bags incorporate internal reinforcements to improve stability, stackability, and space utilization.Key Structural Features

- Internal Baffles — Additional fabric panels, nets, or strings sewn across each of the four corners. These baffles often include holes to allow material flow while preventing excessive bulging.

- Construction Types — Commonly built on 4-panel, U-panel, or tubular bases, with baffles added for reinforcement.

- Shape Retention — When filled, the bag forms a stable square profile (with slightly rounded corners), making it far more rigid than circular or non-baffled designs.

Key Advantages

- Improved Stability and Stackability

Baffles prevent bulging, allowing safe stacking (often higher than standard bags) and reducing the risk of tipping or damage during storage and transport. - Optimized Space Utilization

Square shape maximizes warehouse, truck, or container space—up to 30% more efficient than non-baffled bags. - Higher Capacity and Reduced Waste

Holds more product in the same footprint; minimizes spillage and material loss. - Enhanced Safety and Handling

Reinforced structure improves forklift handling and reduces deformation under heavy loads. - Cost Savings

Fewer shipments needed due to better space efficiency; lower transportation and storage costs (despite being 15-25% more expensive upfront).

Common ApplicationsBaffle bags are ideal for dry, free-flowing, or fine materials:

- Agriculture → Grains, seeds, fertilizers, animal feed.

- Food & Pharmaceuticals → Powders, flour, sugar, starch (food-grade options available).

- Construction → Sand, gravel, aggregates.

- Chemicals & Minerals → Powders, pellets, resins (combine with Type B/C/D for static control).

Note: Not recommended for large, bulky, or low-flow materials that may get caught in baffles.